Documentation grand piano by Gregor Deiss, 1815

Exact surveying establishes a reference for reconstruktion of the instrument and therefore requires utmost exactitude and precision. A first step is visual inspection for planning the proceedings of survey. For the Deiß grand a combination of procedures is used:

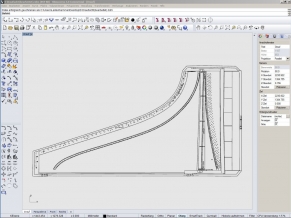

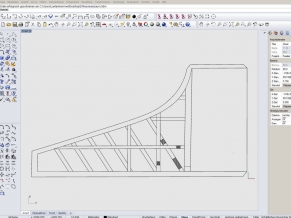

- tactile measuring using a Faro 7 links 3D scan arm:

- with straight tip for locating tuning, bar and end pins

- with angled tip for components not accessible otherwise

- with ball tip for measuring the case

- x-ray tomography for 3D survey of resonance elements (soundboard, ribs, struts, joints)

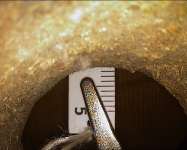

- boriscopic survey (position and basic measuring of struts, traces of tools and work processes, materials)

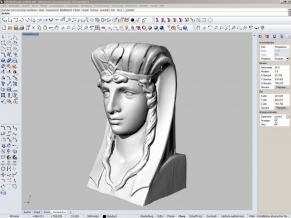

- laserscan of the karyatids

- self made measuring rod for a preliminary survey of the internal resonance chamber

Faro scan Arm

Boriscope

Faro-Laserscan

© Greifenberger Institut für Musikinstrumentenkunde | info@greifenberger-institut.de